Polysulfide PolymersTHIOKOL® LP / NPS-282 / FLEP™ Feature

THIOKOL® LP Major application

- Insulating Glass with THIOKOL® Sealants Boasts a Large Market Share

-

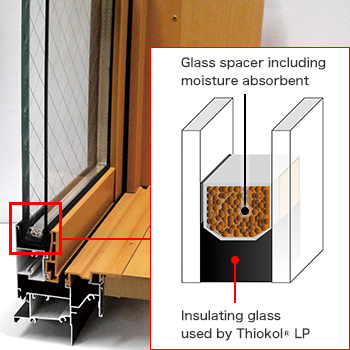

There are various types of insulating glass sealants. Cross section of Inslation glass

Cross section of Inslation glass

A glance at Table 1 makes it clear that polysulfide-based, that is, THIOKOL® sealants, best display all the properties of insulating glass.Properties of insulant glass

-Thanks to the high degree of heat insulation of the dry air tightly sealed up between the panes of plate glass, energy can be saved.

-When, for example,(particularly in the winter) there is a big gap in temperature between the inside and the outside of a room, condensation will from on the inside of a single glass pane, while in the case of insulating glass, thanks to the insulation effect of the dry air between the panes, there is hardly any condensation on the inner pane because its temperature falls only slightly. As a result, there is no obstruction of the view through the glass and no staining or other damage to the walls or the floor resulting from condensation.

Table 1 Performance comparison of sealant bases for insulating glass

| Property (Type) |

Adhesion | Steam permeability |

Structural strength |

Weather resistance |

Others |

|---|---|---|---|---|---|

| Polysulfide (2-part type) |

○ good |

○ low |

○ high |

○ good |

Good worldwide parformance record; stability |

| Silicone (2-part type) |

△ inferior wataer resistance |

× high |

○ high |

○ good |

Due to the volatility of low-molecule components, the glass surface soils easily |

| Polyurethane (2-part type) |

○ good |

○ low |

○ high |

△ high surface deterioration |

Poor performance record |

| Butyl hot-melt type (1-part type) |

× tackiness diminished at low temp:no chemical adhesion |

○ very low |

× slippage occurs |

× | Prompt delivery possible |

The polysulfide sealant, with 3.5~4.0g/㎡/24h, has only 1/5 of the steam permeability of silicon; insulating glass gets hardly clouded; moreover, even under outdoor exposure over a long time friction adhesion of 10~15kg/2.45cm is maintained. Possessing excellent strength and weather resistance, the polysulfide sealant is a well-balanced, easy-to-use sealing material.

Others application of Polysulfide sealant

Construction and civil engineering

In addition, Raw materials for elastomers with outstanding flexibility and dimension stability as well as an epoxy modifier that provides flexibility and adhesion to wet surfaces.

- Impression materials

- Adhesives, Injections

- Printing blankets ETC